Know-How "Made at STEINERT"

We have never left the high quality of ANOFOL to chance. Back in the 1960's, STEINERT was already using ANOFOL aluminium strip for in-house electro technical applications in the field of separation and lifting technology, making the company a pioneer in the manufacturing of anodised aluminium strips. Using this expertise and experience as a basis, STEINERT continuously develops and optimises the processes for manufacturing ANOFOL.

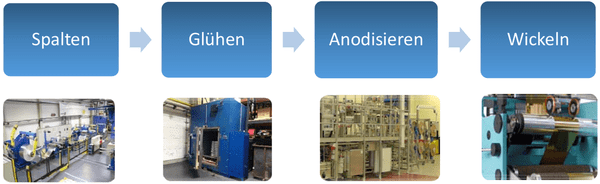

ANOFOL offers “All from a single source” – from slitting, annealing and anodising aluminium strip up to winding high precision coils.

We make more of Aluminium

Since more than 40 years STEINERT is producing ANOFOL anodised aluminium strip. STEINERT's sophisticated technology has made ANOFOL a highly sought-after product for high performance conductive materials used in electrotechnical applications

Essential to this: state-of-the-art, highly-precise production methods and stringent quality controls that guarantee consistent premium quality. Whether standard products or customised individual coils, the extensive ANOFOL range consists of aluminium strips from 3.0 mm up to 260 mm wide and 0.05 mm up to 1.5 mm thick for a broad spectrum of electro technical applications.

The aluminium strip with many adventages

In many industrial sectors today, ANOFOL is the smart alternative to conventional copper wires. The reasons are obvious: not only is aluminium more cost-efficient, it also has a higher temperature resistance and weighs less. Moreover, aluminium enables precise production of extremely thin, flat strip with minimum tolerances, which in many cases, also means economic benefits.

![[Translate to English:] Steinert Logo [Translate to English:] Steinert Logo](/fileadmin/user_upload/anofol/content/csm_STEINERT-01_836000db30.jpg)

![[Translate to English:] metalloxyd Logo [Translate to English:] metalloxyd Logo](/fileadmin/user_upload/anofol/content/logo_metalloxyd.gif)